Alumina silica fire brick is a kind of alumina silica refractory materials, alumina silicate refractory brick has features of high refractoriness, good erosion resistant and high strength. Aluminum silicate refractory brick includes many types of firebricks such as silica brick, fireclay brick, High alumina brick, mullite brick and corundum Brick. alumina silica fire brick can be used for all kinds of thermal equipment.

Classification of Alumina Silica Fire Brick

According to the order of increasing content from SiO2 to Al2O3, aluminum silicon fire brick is classified into the following categories

Silica brick: the content of SiO2 is greater than 93%,

Clay brick: the content of Al2O3 is 30%-48%,

High alumina brick: the content of Al2O3 is greater than 48%,

Mullite brick: the content of Al2O3 is greater than or equal to 72%, and the content of SiO2 is greater than or equal to 28%,

Corundum brick: the content of Al2O3 is more than 90%.

Application of Alumina Silica Fire Brick

Silica brick is mainly used to build coke oven, glass kiln, ceramic kiln, carbon calcinations furnace and is not suitable to be used in heating equipment with temperature fluctuation under 600 ℃.

Clay brick is always used in blast furnace, hot blast heater, heating furnace, power boiler, lime kiln, rotary kiln, ceramic kiln and calcining kiln.

High alumina brick is mainly used in steel manufacture, non-ferrous metals industry and other industries.

Mullite brick is used in all kinds of industry furnace hot-face lined and backing lining in metallurgical industry, petrochemical industry, building materials industry, ceramic industry, and mechanical industry.

Corundum brick can be used in blast furnace, hot blast stove, glass furnace and etc.

Alumina Silica Fire Brick Features

- High refractoriness,

- Good thermal shock resistance,

- Strong acid erosion resistance,

- High temperature strength,

- Low thermal expansion coefficient,

- High thermal conductivity.

Specifications

| Item | RSAS60 | RSAS70 | RSAS75 | RSAS80 |

| AL2O3(%) | ≥60 | ≥70 | ≥75 | ≥80 |

| SIO2(%) | 32 | 22 | 20 | ≥18 |

| Fe2O3(%) | ≤1.7 | ≤1.8 | ≤1.8 | ≤1.8 |

| Refractoriness °C | 1790 | >1800 | >1825 | ≥1850 |

| Bulk density,g/cm3 | 2.4 | 2.45-2.5 | 2.55-2.6 | 2.65-2.7 |

| Softening temperature under load | ≥1470 | ≥1520 | ≥1530 | ≥1550 |

| Apparent porosity,% | 22 | <22 | <21 | 20 |

| Cold Crushing strength Mpa | ≥45 | ≥50 | ≥54 | ≥60 |

Alumina Silica Fire Brick Manufacturer

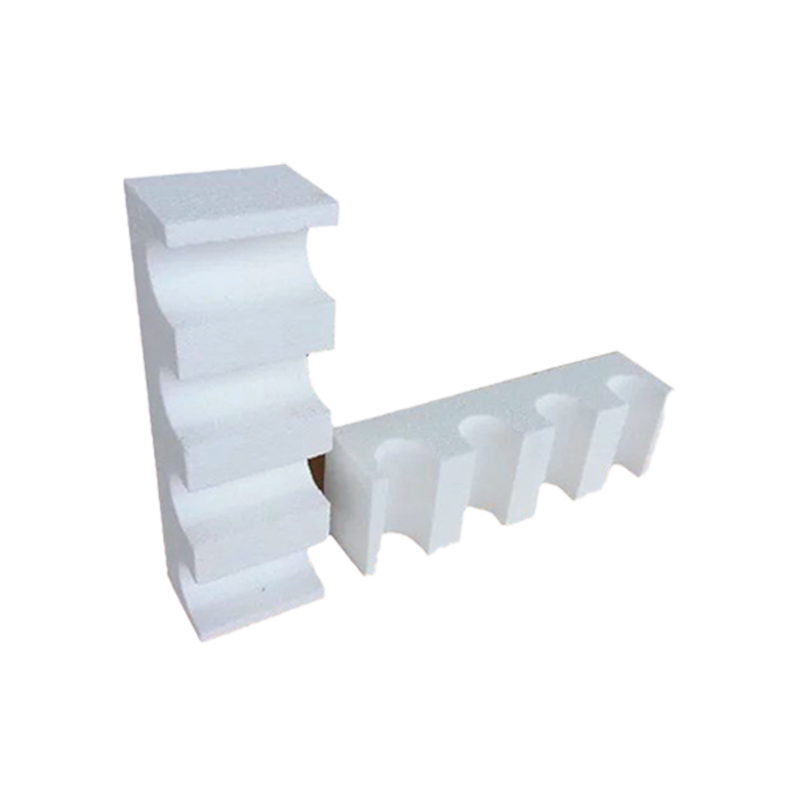

RS refractory manufacturer as one of the leading kiln refractory bricks manufacturer is specialised on cutting and shaping refractory bricks according to customer requirement, which can produce high quality alumina silica fire brick for you.