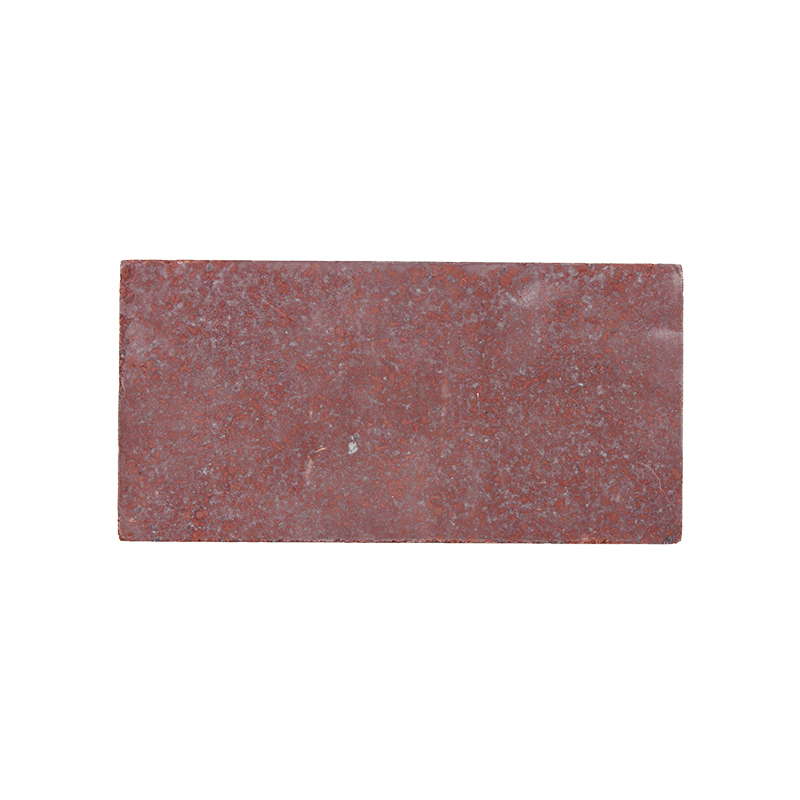

Magnesite chrome block uses quality magnesia and chromic oxide as the raw material, molded through high press and fired in the high temperature. magnesia chrome bricks have features of large crystal and high direct bonding rate. and magnesite chrome fire bricks have good cracking resistance and good acid slag erosion resistance with low alkaline property. magnesite chrome block is the ideal lining brick material for finery out of furnace, electric furnace, glass furnace, melting furnace and rotary cement kiln.

Properties of Magnesia Chrome Bricks

- High flexibility,

- Low thermal conductivity,

- High temperature strength,

- Good thermal shock resistance,

- Strong furnace slag erosion resistance.

- Classification of Magnesia Chrome Bricks

Due to the quality of magnesia chrome bricks, magnesia chrome brick is divided into ordinary magnesia chrome brick, direct bonded magnesia chrome brick, semi bonded magnesia chrome brick, rebonded magnesia chrome brick and so on.

Magnesia Chrome Bricks Manufacturing Process

Magnesia chrome bricks are made of bonded common sintered material, and eliminate loose effect caused of the expansion when producing the spinel by the reaction of MgO and Cr2O3, Al2O3 or FeO. Moreover, there is also unburned magnesite chrome fire brick such as unburned magnesite chrome block is made of inorganic magnesia saline solution. and unburned magnesia chrome brick is simple and low cost. this kind of magnesia chrome brick has great thermal stability, but its high temperature strength is lower than burnt magnesia chrome brick.

Rongsheng Refractory Magnesia Chrome Bricks Specifications

Common magnesite chrome brick

| Items | Physical and Chemical characters | |||||

| MGe-16A | MGe-16B | MGe-12A | MGe-12B | MGe-8A | MGe-8B | |

| MgO % ≥ | 60 | 45 | 60 | 55 | 65 | 60 |

| Cr2O3 % ≥ | 16 | 16 | 12 | 12 | 8 | 8 |

| Apparent Porosity % ≤ | 19 | 22 | 19 | 21 | 19 | 21 |

| Cold Crushing Strength MPa≥ | 35 | 25 | 35 | 30 | 35 | 30 |

| Refractoriness Under Load °C≥ | 1650 | 1550 | 1650 | 1550 | 1650 | 1530 |

Direct-Bonded magnesite chrome brick

| Items | Physical and Chemical characters | ||||||

| ZMGe-16A | ZMGe-16B | ZMGe-12A | ZMGe-12B | ZMGe-8A | ZMGe-8B | ZMGe-6 | |

| MgO % ≥ | 60 | 58 | 68 | 65 | 75 | 70 | 75 |

| Cr2O3 % ≥ | 16 | 16 | 12 | 12 | 8 | 8 | 6 |

| SiO2 % | 1.5 | 2.5 | 1.5 | 2.5 | 1.5 | 2.5 | 2.5 |

| Apparent Porosity % ≤ | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| Cold Crushing Strength MPa ≥ | 40 | 40 | 45 | 45 | 45 | 45 | 45 |

| Refractoriness Under Load °C ≥ | 1700 | 1650 | 1700 | 1650 | 1700 | 1650 | 1700 |

Application of Magnesia Chrome Bricks

Magnesia chrome brick is mainly used in metallurgical industry, such as building open hearth furnace, furnace top of electrical furnace, out of finery and all kinds of non ferrous smelting furnace. magnesite chrome block is also used in position of burning zone of rotary cement kiln and regenerative chamber of glass kiln.

Magnesia Chrome Bricks Manufacturer from RS Refractory Factory

RS refractory factory is a professional magnesia chrome bricks supplier that established in the early 90s of twenty century. RS refractory factory has specialized in magnesite chrome fire bricks for more than 20 years. if you have some demand of magnesite chrome block, or have some questions on magnesia chrome brick about physical and chemical indicators, please contact us for free. Rs refractory factory as a professional magnesite chrome fire bricks manufacturer in china, has some competitive advantages as follows:

- Competitive Price: Make the products competitive in your market,

- Abundant Experience: Prevent cracks and twist in bricks,

- Different Moulds: Save mould fees for you,

- Strict Quality Control: Meet clients’ quality requirement,

- Large stocks: Guarantee prompt delivery,

- Professional Packing: Avoid damage and secure the goods in transportation.