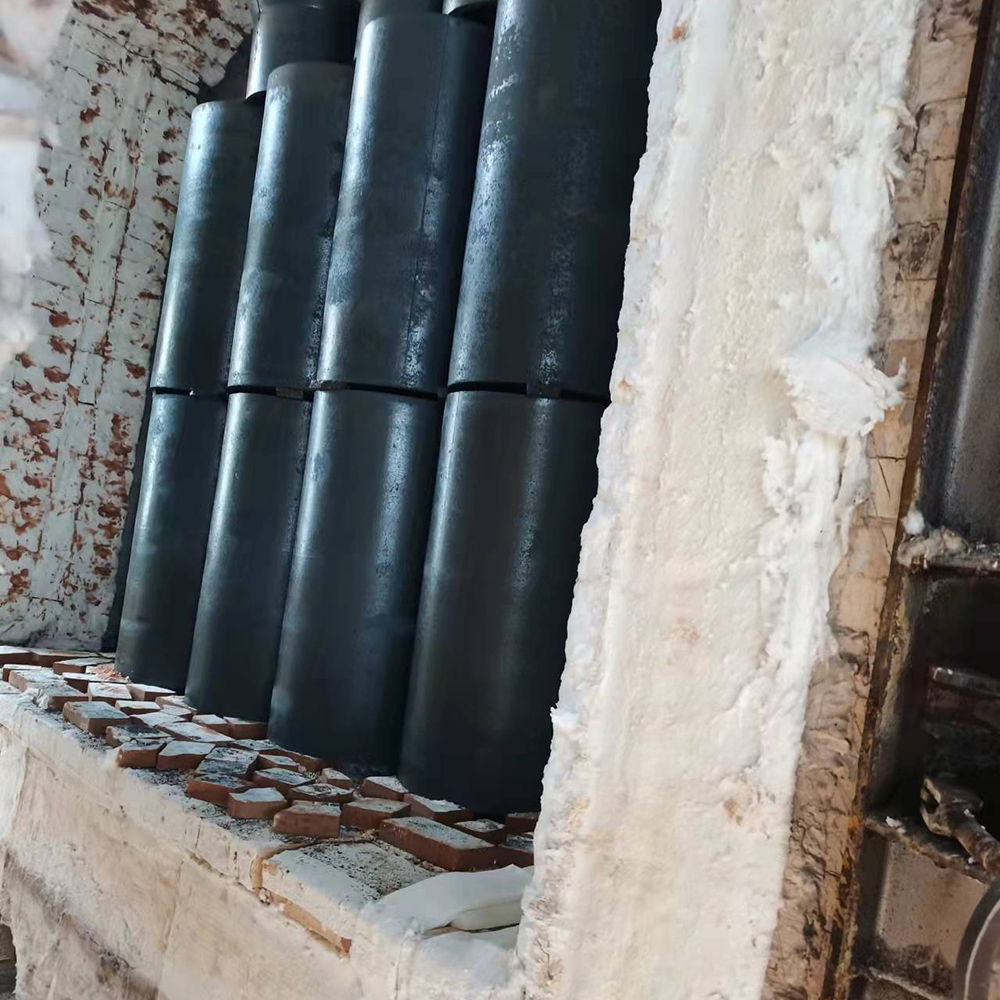

Silicon carbide sagger produced by Rongsheng Group have the characteristics of good flexibility, not easy to crack, and long service life, and also the large capacity of the sagger increases the output, guarantees the quality, saves labor and lots of costs.

The company has successively supplied customers in more than 60 countries. Through our company’s continuous improvement of products and strict control of the production process, the stability of product quality has been improved, so that customers can get real benefits and have won unanimous praise from users.

Technical Data:

|

No. |

Particulars |

Parameter |

|

1 |

SiC(%) |

≥85% |

|

2 |

SiO₂(%) |

≤10% |

|

3 |

Fe₂O₃(%) |

<1% |

|

4 |

Bulk Density in g/cm³ |

≥2.60 |

|

5 |

Cold Crushing Strength(MPa) |

≥100 |

|

6 |

Apparent Porosity(%) |

≤18 |

|

7 |

Refractoriness,(°C) |

≥1700 |

The product is made of silicon carbide as the main raw material, adding a variety of chemical wear-resistant raw materials and anti-oxidant, effectively improving the wear resistance of the product, using SiO2 micro powder as the high-temperature bonding phase, a high-performance silicon carbide products by high-temperature firing, with the

1. Dimensional stability at high temperatures, resistance to deformation and high strength at high temperatures

2. Resistance to thermal shock, abrasion and corrosion

3. Anti-oxidation and erosion resistance

It can be widely used in: electric power, steel plant slag flushing trench, coal chemical industry, mining, transportation pipeline.

Technical Data:

|

Technical Performance |

Bulk Density |

Abrasion Resistance |

Moh’s Hardness |

CCS |

|

g/cm³ |

% |

MPa |

Mpa |

|

|

Silicon Carbide Tubes |

2.7 |

1.66 |

>9.0 |

21.2 |